-

StatusCompleted

-

Status date2016-08-31

Objective 1:

to representatively test Harmonic Drive ® gears already used or foreseen in future telecom space applications (Solar Array Drive Mechanisms, pointing and deployment mechanisms, etc...) with new, European, space suitable lubricants.

Objective 2:

to produce data sheets for Harmonic Drive ® gear for space applications, in which performance parameters are given in conjunction with space-rated lubricants and for duty cycles typical for space applications

The Harmonic Drive ® gears are a modern and highly performing alternative to classical gear technologies and have a remarkable performance record in European and US applications.

The output of this activity provides the space community with reliable test data and information about the performance of space rated Harmonic Drive ® gears at various speeds and temperatures. Space mechanisms providers have received via this activity important data about expected life of harmonic drive gears. This lowers the risk of designing new mechanisms with harmonic drive gears with certain life expectation and removes the need to early breadboard life test.

The results of this activity certainly contribute to European independence, strengthening of the position of this European product and increasing its competitiveness on the international market.

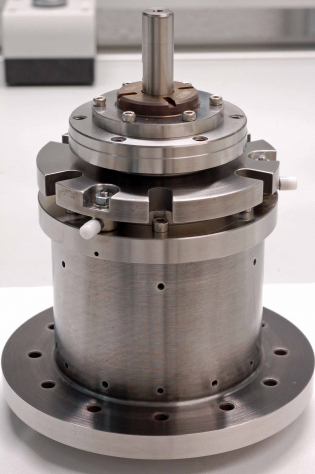

Harmonic Drive ® gears are composed from just 3 parts: A solid steel ring with internal teeth called Circular Spline, a special ball bearing mounted on an elliptical plug with a central hub (Wave Generator) and a flexible cylinder with external teeth. The Harmonic Drive ® gear provides a high ratio up 320 in one stage. There is no toothing at the Wave Generator, what is the fast turning input part. The relative speed of the toothed parts is relatively low, so wearing is not a critical issue. Furthermore wearing is compensated by the radial preload in the toothing, what is “built-in” due to the principle of function.

The activity started with end used technical survey and specification of requirements for space-rated Harmonic Drive ® gear.

Review of suitable space lubricants was performed and two typically used lubricants (PFPE and MAC) were selected.

Based on the end user survey results two Harmonic Drive ® gears type HFUC size 20 and gear ratio 160 were selected and manufactured.

Efficiency and life tests were performed on the gears at European Space Tribology Laboratory (UK). The tests were performed in ambient and thermal vacuum conditions at extensive range of speeds and temperatures.

Based on the test results efficiency model was devised and datasheet for the two different lubrication schemes were established.

The tests have demonstrated that:

- efficiency of the harmonic drive gears has been improved thanks to the selected lubrication scheme

- life of the gear has increased significantly as compared to status prior this activity.

Activity has been completed in June 2016.