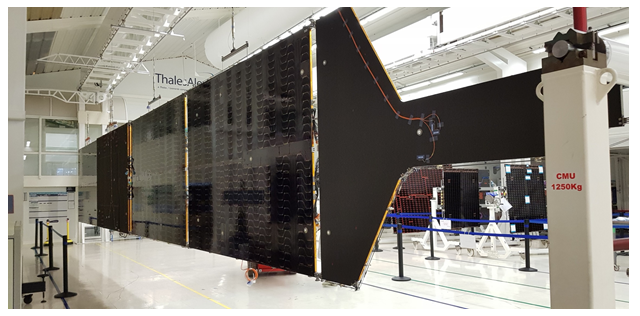

A new High Power Solar Array (HPSA) product family with enhanced performances and competitiveness has been developed by Thales Alenia Space, France, under the ARTES Competitiveness & Growth programme. The different solar array configurations fit perfectly with the power range of the new generation of fully electric geostationary satellites.

The future is electric. Electric propulsion is considered by all space actors as a key and revolutionary technology for the new generations of commercial satellites. And with good reason – an all-electric geostationary satellite can reduce launch weight by as much as 40%; or alternatively permit the satellite to increase its payload.

Having solar arrays which are adapted and keep pace with the growing technology and level of innovation is essential as this satellite market becomes increasingly competitive.

The project team developed a GaAs Solar Array product family to complement the new generation Spacebus Neo platform with enhanced performances and competitiveness. GaAS (Gallium arsenide) solar cells are the most efficient solar cells, turning photons from sunlight into electricity.

“The aim of this development was to establish a family of products that are capable of supporting a full range (up to 15) of HPSA configurations, making it possible to start application programs with minimum effort – thanks to the commitment to only propose an ‘off-the shelf’ product,” says Evelyne Simon, ESA Technical Officer.

The different Solar Array configurations – from 4 to 6 panels per wing, with either small or large panel sizes – fit with the full power range of the new generation of full electric geostationary satellites.

“Adopting HPSA on Spacebus NEO brings a significant competitiveness advantage with regard to state-of-the-art solar arrays on GEO Telecom satellites,” says Patrick Benard, Program Manager, Thales Alenia Space

The scope of the project covered the entire design (electrical, mechanical and thermal) as well as manufacturing, assembly and test activities – from a components level up to the first commercial application qualification and launch in 2020.

Key challenges involved factoring in the electric orbit raising radiation environment, in particular ATOX (Atomic Oxygen or ‘ATOX’ in the Low Earth Orbits can cause severe damage), but the team rose to the challenge to bring a competitive product to market – and in record time.

“During its development this project was on track for its first commercial launch in 2020, demonstrating an incredibly short time-to-market,” says Evelyne. “Not only that, we improved on previous Solarbus generation products in terms of mass in the same power range.”

“Thanks to the ARTES C&G programme, Thales Alenia Space can propose this cutting edge technology for all GEO applications with a significant reduction in effort and risk,” says Patrick Benard, TAS. “The HPSA is the natural continuation of the Thales Alenia Space solar array product line.”

Following the successful launch of the first commercial application, in orbit data has shown that the HPSA product line is fully operational. In Q1-2021, TAS has received a spectacular 7 orders for Spacebus NEO, using 4 different Solar Array configurations. The future seems sunny indeed for HPSA.