A novel pair of robotic arms have become a hardware hit for Euro Heat Pipes, a European company specialising in space thermal control. The unique fully-articulated robotic thruster arms, which help with Electric Orbit Raising, are the brainchild of the Belgian company who developed the innovation under ESA’s ARTES Competitiveness & Growth programme.

Several P-DPS flight sets have now been delivered to Airbus Defence and Space, with three sets already launched successfully and two more Flight Sets currently on the assembly line.

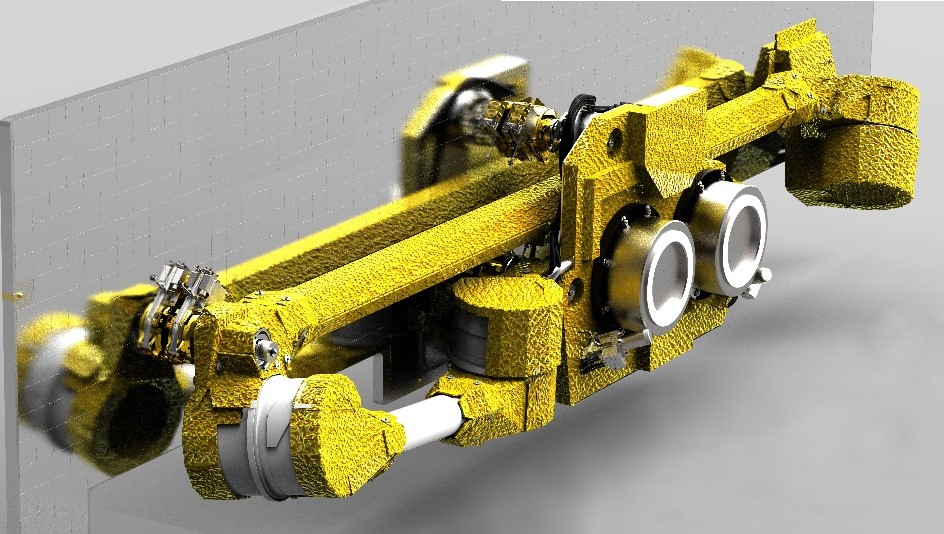

The twin arms form part of a Propulsion Deployable and Pointing System (P-DPS) for Electric Orbit Raising – part of a paradigm shift which is bringing electric propulsion to the forefront of the space scene – particularly in the geostationary market.

While electric propulsion has been around for many years, the emergence of new applications is seeing its resurgence. Without the bulky propellant tanks used in chemical propulsion it’s possible to produce significant satellite mass savings – freeing up capacity for higher revenue-generating payloads.

The P-DPS is a critical component of the electric propulsion system; so the 3-metre-long,

3-jointed arms – at the end of which Hall-effect thrusters are mounted – had to be robust and reliable to ensure flawless flight.

System architecture

The arms are launched in stowed configuration, and are released and deployed during the first days of the mission. The arms orientate the satellite’s Hall-effect thrusters allowing exact control of the thrust direction and attitude during different phases of the mission.

Mario Toso, the ESA Technical Officer who oversaw the project’s initial development with ARTES says: “Instead of having different thrusters embedded at corners of the satellite, the twin arms, possessing three degrees of freedom, can be moved freely about its body on an extremely versatile basis,” he says. “The thrusters mounted at the end of these arms are fired jointly for orbit raising. After that, they are employed on an everyday basis for station-keeping.”

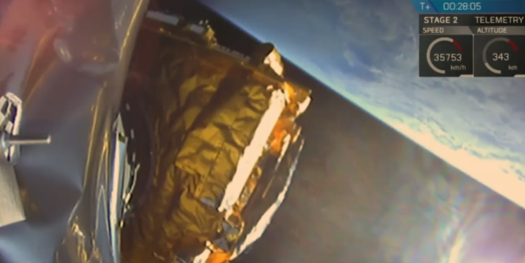

The twin arms were in fact the ‘innovative addition’ to the new Eurostar E300 all-electric platform and credited with Eutelsat-172B reaching its target position in geostationary orbit – just four months after its launch – an industry record for the fastest all-electric orbit-raising. The satellite’s builder Airbus DS said the record time had been achieved thanks to the deployable robotic arms, among other innovations.

When compared to existing thruster module assemblies, the arms have clear benefits – namely their competitive cost and  mass benefits. They also support a wide range of thruster variants, are an enabler for full electrical telecom satellites, have a low-shock, non-explosive release from the launch lock assembly and a proven actuating life.

mass benefits. They also support a wide range of thruster variants, are an enabler for full electrical telecom satellites, have a low-shock, non-explosive release from the launch lock assembly and a proven actuating life.

“We’ve had data back to make sure the system is operating well and the in-orbit tests performed and the in-flight data have shown that the mechanisms are operating flawlessly,” says Paul Greenway, ESA Technical Officer of the P-DPS project.

“The P-DPS programme has allowed EHP to move from a commodity manufacturer to a successful pointing mechanism integrator. Support from ESA through ARTES and the ATLAS programme were key to this success,” says EHP Project Manager, Olivier Leurquin. “The P-DPS contributes to Eurostar 3000 competitiveness allowing AIRBUS DS to propose a reduced cost per transponder; access to a larger range of launchers, with cheaper launch costs.”

“The P-DPS programme has allowed EHP to move from a commodity manufacturer to a successful pointing mechanism integrator. Support from ESA through ARTES and the ATLAS programme were key to this success,” says EHP Project Manager, Olivier Leurquin. “The P-DPS contributes to Eurostar 3000 competitiveness allowing AIRBUS DS to propose a reduced cost per transponder; access to a larger range of launchers, with cheaper launch costs.”

“This is a valuable piece of hardware which enhances the overall competitiveness and performance of E3000 satellites in order to fully answer operators’ needs and requirements. EHP is already working in close collaboration with Airbus DS on the development of a new generation to be used on a recurring basis on the Airbus DS NEOSAT platforms,” says Olivier Leurquin, Euro Heat Pipes.