-

StatusCompleted

-

Status date2019-05-21

-

Activity Code5C.214

For the space market the continuous evolution of the communication segments leads to a trend of using traveling wave tubes (TWTs) with higher frequencies (mainly in the Ka-Band) and increased output power. The high voltage and an increase of dissipated power in the TWT collector raised the questions for new materials with outstanding properties.

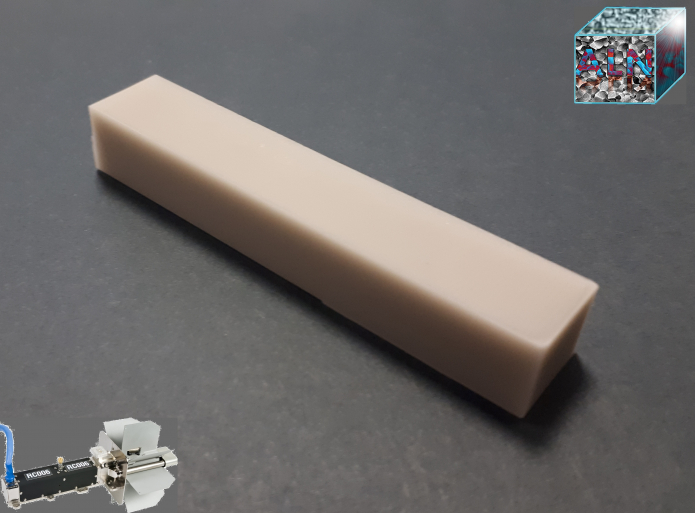

Attention was paid to aluminium nitride (AlN) due to its high thermal conductivity and the good electrical insulation.

For Thales it was mandatory to focus on the reliability aspect, as the TWTs are designed for long-term applications and cannot be replaced during their mission. Therefore a reliable material supply, that is stable in quality and quantity on a long term basis, was the most important prerequisite for a fundamental change of the materials, when it is envisioned to be introduced subsequently in a series of tube families.

The AlN material implemented in space traveling wave tubes allows the improvement of the thermal behaviour and margin for future high power tube development.

AlN is used for the electrical insulation of the High Voltage sections of the tube, predestinated by the apparent physical properties of the AlN, especially its high thermal conductivity and its good electrical insulation for high potentials. In competition to other insulating materials it has the advantage of non-toxicity and is less expensive and less limited in geometry than some others.

The AlN material was implemented in the high power families of the travelling wave tubes. The apparent high dissipation, experienced in this class of tubes, is compensated by the advanced ceramic leading to a reduction of the maximum temperature inside the tube. Consequently, this had a positive impact on the tube life. Furthermore, still applying the same design rules, the door was opened for even higher output power, due to the use of the AlN.

The TWT is a device for microwave amplification. Therefore, it is designed to enhance the incident microwave radiation by interaction with an electronic beam.

There are three parts that represent the tube: electron generation, interaction and electron de-celeration. The electrons need to be de-celerated, as the efficiency of the microwave/electron-beam interaction is limited. High voltage potentials are used to slow down the electrons in an efficient way. For the generation of the electrical potential differences the electrodes need to be insulated versus ground by ceramic insulators.

High power TWTs are designed such, that they can handle maximum microwave energy, which is automatically correlated to the tube efficiency. So, - under the consideration of a sufficient margin – the following main parameters are pushed to their physical / material limits:

- Temperature

- Thermo-mechanical stress

- Thermal gradients

- Thermal conductivity

- Breakdown voltage

- Electrical insulation

- Long-term stability

The insulating ceramics for high voltage reasons play an outstanding role in this assembly and need to be chosen very carefully. Moreover, they have to fulfil all of the above criteria, which sometimes force to choose a compromise on the material – due to some of the parameters.

The project is divided into two phases. Phase 1 is focused on the stability/reliability of AlN material properties and the availability of such AlN on the market, closed by a Baseline Design Review (BDR).

For Phase 2 the collaboration with the supplier is the main subject, in order to achieve a longterm securization of the achieved results of Phase 1. Material screening of the first phase is transformed into material design, matching Thales needs on a longterm basis. After verification of the AlN material on a travelling wave tube this 2nd phase is finalized by the Final Review (FR).

The technical objectives of the breadboard were successfully met. The activity is completed.