-

StatusCompleted

-

Status date2015-12-09

The main objective is to develop an advanced Cool Gas Generator for satellite mono-propellant propulsion system re-pressurisation. A Cool Gas Generator produces pure nitrogen gas at ambient temperature from a solid propellant. The requirements for such a generator and the way it will work with and interface with the satellite propulsion system will be established. The Cool Gas Generator will have a nitrogen gas production of 500 litres and a mass performance of 250 nl/kg. The expected volumetric performance will be 290 nl/l.

The Cool Gas Generator will be based on the proven Proba 2 and Delfi N3xT Cool Gas Generators but improved using technologies developed in national programmes.

The study will end with a conceptual design of such a Cool Gas Generator including a development plan and other direction for the full hardware development.

The first key challenge for this project is to integrate the Cool Gas Generator in the propulsion system in such a way that the impact on the propulsion system is as small as possible while allowing the maximum of the advantages that the re-pressurisation system has to offer for the satellite. The second challenge is to design a Cool Gas Generator that is as small and light as possible without too much risk on the technology.

The main benefit of the Cool Gas Generator is that with the same tanks and minimal changes to the propulsion system the propellant load can be increased with as much as 25%. This will increase the manoeuvring capability or increase the satellite life. Alternatively, the tank size can be decreased for the same propellant load. This can have a knock-on effect that may reduce the whole satellite volume and mass, which can lead to a smaller satellite.

The Cool Gas Generator is a non-pyrotechnic device and the pure nitrogen gas produced is of ambient temperature.

Two types of Cool Gas Generators were identified in this study. The first had a nitrogen gas production capability of 600 liters (at 1 bar and 273 K) and was meant for general re-pressurization. The second was a smaller Cool Gas Generator of 150 nl for End-of-Life applications. The Cool gas Generator will be modular so that by making the main cylindrical body longer or shorter different sizes and gas production volumes can be achieved without requalification. The Cool Gas Generator will include a number of new lightweight technologies that will reduce the weight and volume significantly. Typically the 600 liter nitrogen version, a mass of 2.2 kg and a volume of 1.85 l is expected.

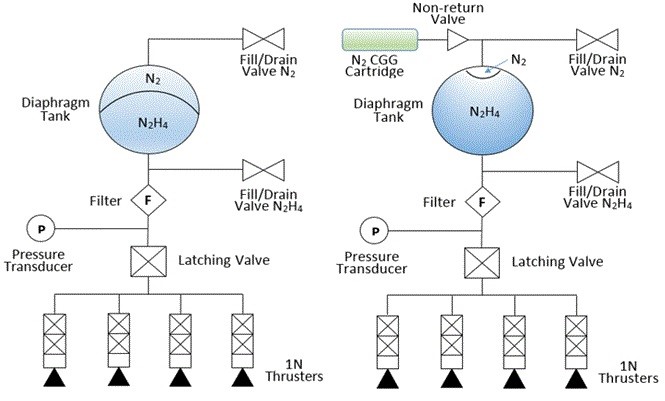

SYSTEM ARCHITECTURE

The Cool Gas Generator will be connected to the nitrogen pressurisation feed line of the satellite. The only other component will be a non-return valve (only in case of a PMD tank). The CGG igniter will be connected to the satellite electrical command bus. When the nitrogen gas in the tank has expanded from typically 25 bars to 5 bars, the CGG will be activated. It will then re-pressurise the tank until 25 bars. Then a normal blow down cycle can start. In this way 25% additional propellant can be loaded into the tank.

In the first phase of the project, a system study will be performed to see how that Cool Gas Generator can best be integrated into the satellite propulsion system. Also the recent developments in the Cool gas Generator technology will be reviewed. The combination of both activities will lead to a realistic set of requirements for the Cool Gas Generator. From these requirements a conceptual design will be made including a development plan and cost estimate. With this the application case and the business plan will be updated.

Status November 2015: the study is closed and technical and business feasibility has been demonstrated. The study team is preparing a proposal for the ARTES 5.2 programme to start actual product development.