-

StatusCompleted

-

Status date2018-01-16

-

Activity Code5C.215

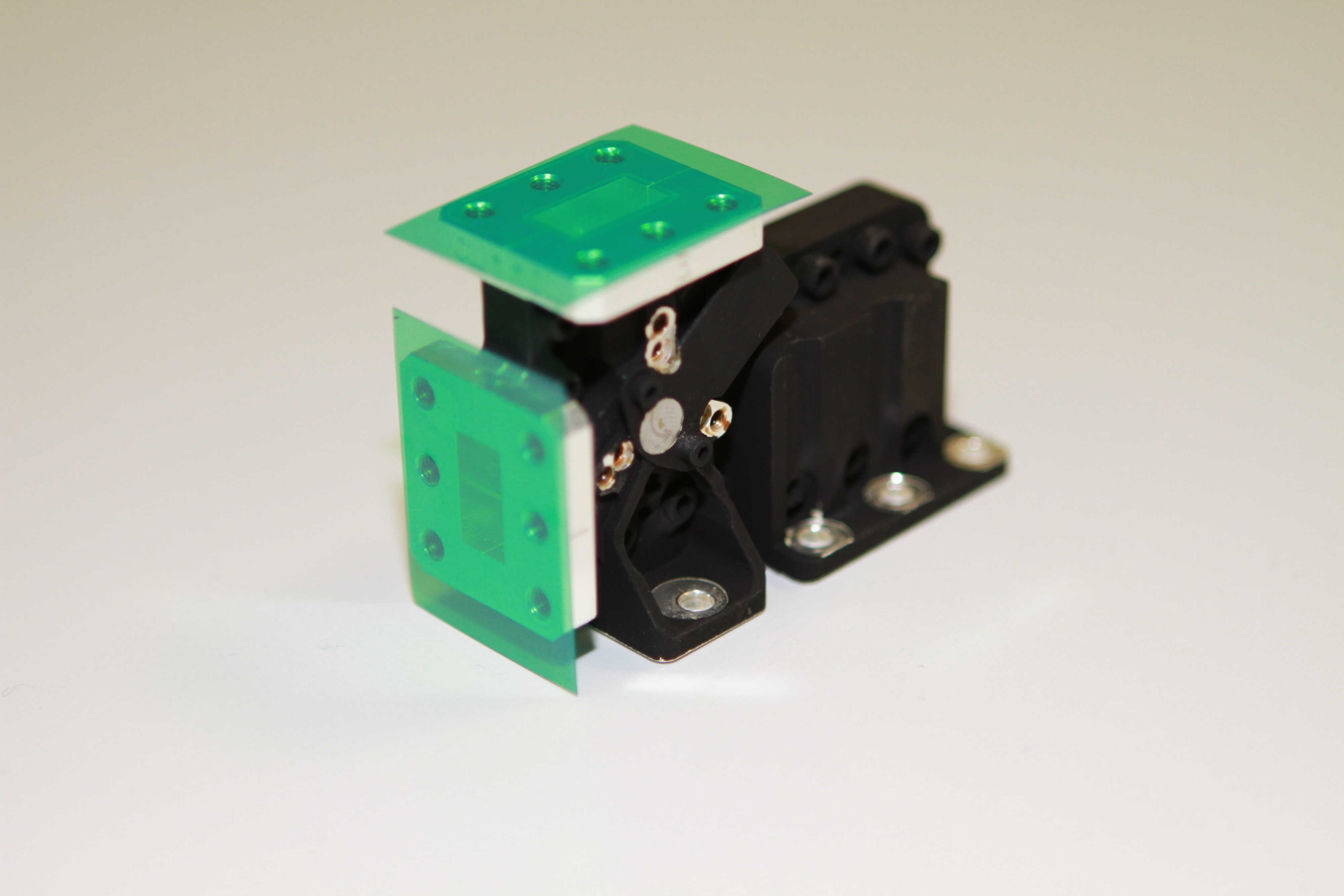

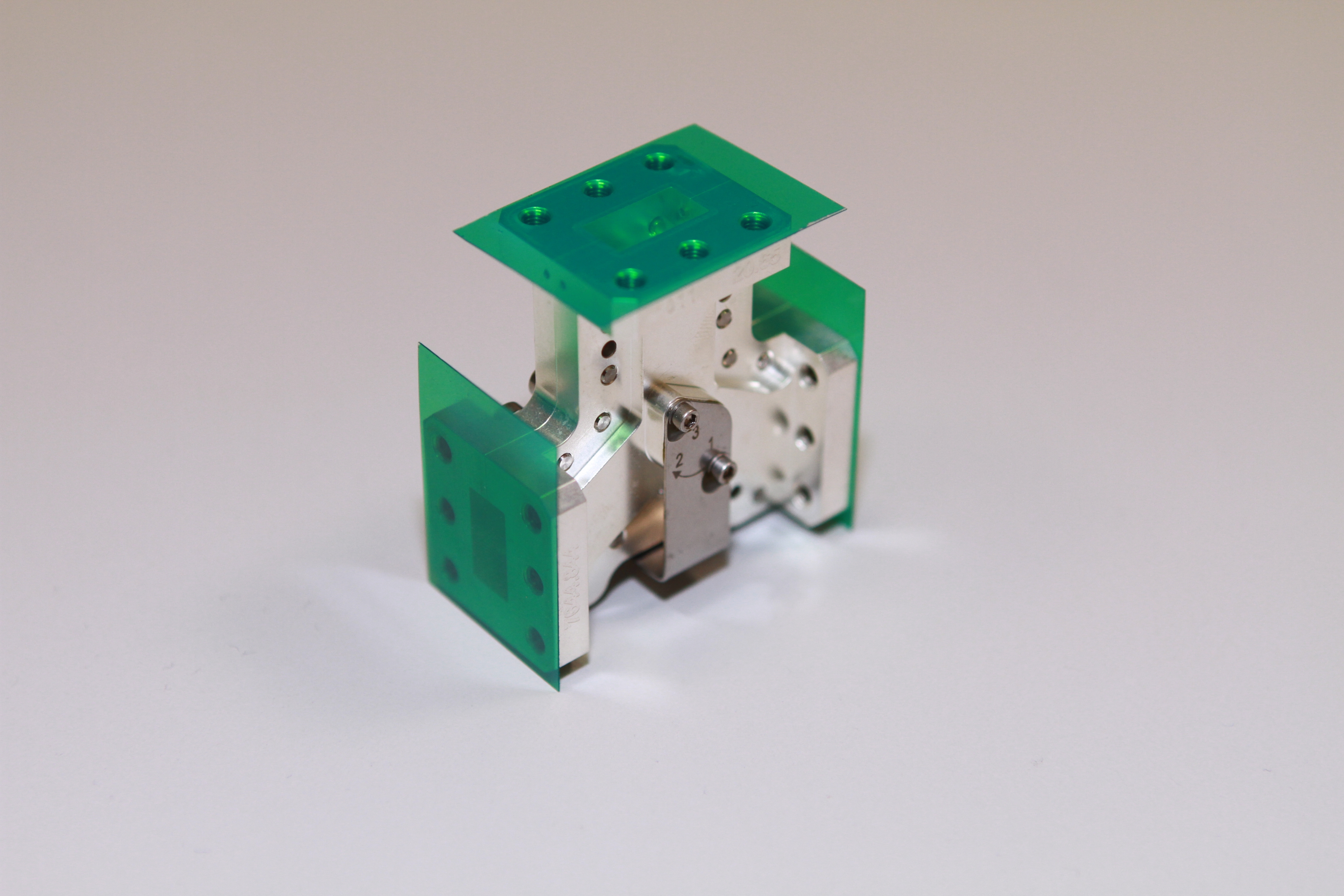

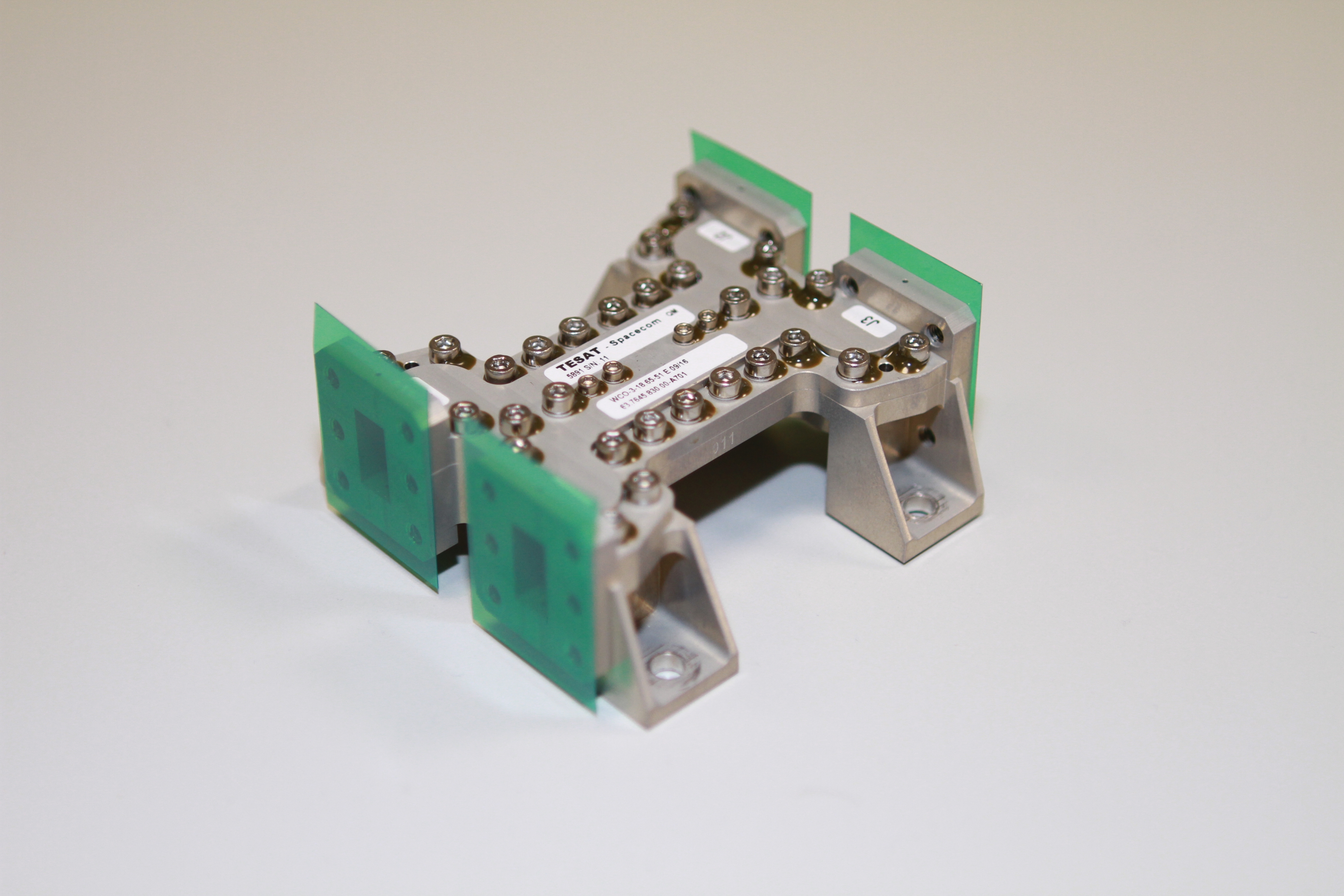

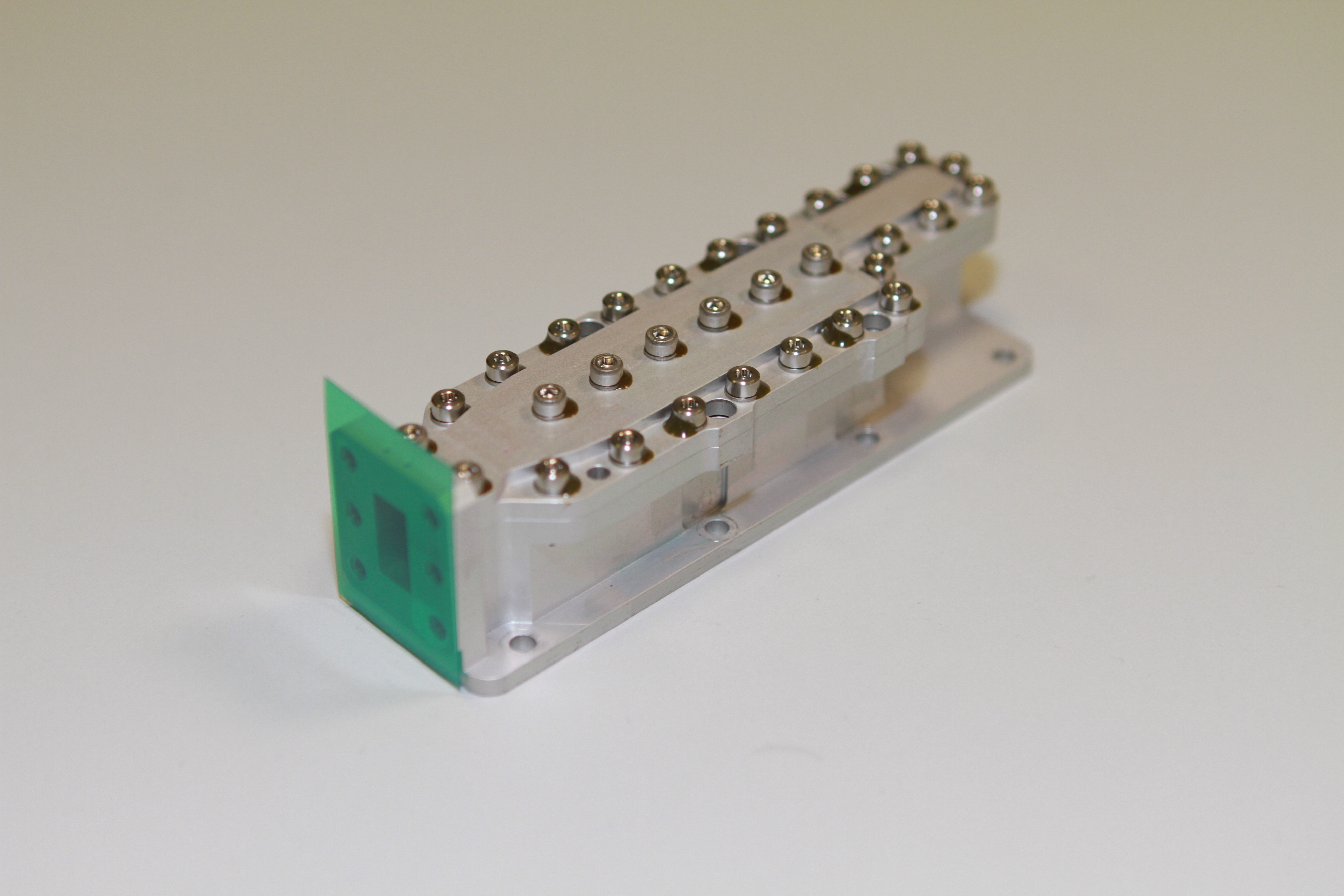

Nowadays Ka-Band components are standard equipments on the passive products market. But the requirements in Ka-Band market regarding power handling have been extended in the last years. Therefore components were necessary, which can fulfil these specifications. The project objective is to develop and qualify a coupler, a load, and a circulator which can handle more power than the present components. During the term of this project a new urgent request occur on the market needs containing a compact isolator. Hence the development of a 600W load was discarded in favour of a compact design of an isolator. The 600W load can be derived from 300W load design.

The main key challenge for the coupler was to balance the amplitude over the wide frequency range. To handle the dissipated energy and therefore to keep the temperature limits of the used materials was the main task in the development of the load. For the circulator the critical challenge was to handle the input power of 300W in the worst case condition which is 600W in total reflection.

The main quest in the compact isolator development was to integrate the load and circulator in compact design in consideration of the dissipated power.

- Extension of input power

- Compact of design

- Improvement of manufacturing process flow and analysis

The approach in this project was to develop and qualify each component as standalone equipment.

Development of electric design by analysis and by breadboarding.

Development and qualification of materials and processes.

Qualification of fully assembled equipments (EQM level).

The close out of the project was in 2017.

The project has been completed. All 4 components have been developed and qualified from feasibility study to operational.

ESA’s support was vital for achieving robust designs for this equipment, especially for the development of the high power load. Thanks to help of ESA’s experts, we were able to address also fabrication issues early on, allowing us to ramp up our in-house production more rapidly.