-

StatusCompleted

-

Status date2018-06-01

-

Activity Code4F.051

The objective of the project is to design, manufacture and test a high voltage power module breadboard within electronic power conditioners to enable operations at higher temperatures.

The following subjects are covered by the project activity:

- An evaluation on critical identified components, specifically on Silicon Carbide High Voltage Diodes and on High Voltage Capacitors (ceramic and MICA reconstituted).

- An evaluation of a new technology item in order to sustain a high temperature environment in potted HV Module.

The main challenges of this project is to adapt the parts and process of the EPC are :

- To allow operations at a higher base plate temperature than previously authorized by the standard design rules, especially for parts employed in the high voltage areas of the EPC, such as HV diodes and HV capacitors.

- To use SiC technology for High Voltage diodes in an EPC Breadboard.

It is clearly established today that the technology limits to implement another step up in power result from the temperature constraints applicable to the High Voltage conversion to witch the standard design rules are applied.

In addition, such a level of power becomes a severe constraint for the distribution and the revisit of the TWTA architecture could be an asset, such as for example the opportunity to implement the High Voltage converter in the near vicinity of the TWT, with a consequence of higher base plate temperature.

The specific parts and process studied to meet this increased temperature range requirement are:

- A high voltage high temperature capacitor

- The Silicon Carbide technology

- A technology item able to sustain the higher temperature range in high voltage potted modules

This study results in recommendations on the EPC parts and process compatible with new increased temperature limits. Moreover, these parts and processes should also allow for a step up in power capabilities of the EPC, a higher level of manufacturability and an overall better competitiveness, in particular thanks to the Silicon Carbide technology.

The EPC parts and process studied in the frame of this project are specifically evaluated to sustain an increased temperature range:

- High voltage capacitor: a high voltage capacitor able to sustain a higher temperature range is evaluated in the frame of this project

- Silicon Carbide technology: the Silicon Carbide technology represents an opportunity to overcome the limitations of the current Si technology

- Technology item: the evaluation of a corresponding technology specific to a higher temperature range of EPC is also covered by this project.

The selected high voltage capacitor and the Silicon Carbide technology, together with the selected technology, are evaluated at the breadboard level in the second phase of this study. This breadboard is representative of the EPC and of its new temperature range limits.

The EPC mainly consists in a high efficiency high voltage converter providing the various voltages required by the TWTs and also specific controls for the proper operation of them. The architecture of the EPC takes into account high voltage constraints, thermal constraints, mechanical constraints, and thermo-mechanical constraints. This is implemented through a careful electric design (component placement), insulation, and surrounding technologies (type of resins used, mechanical parts involved,…).

This project’s aim is to develop technologies allowing the EPC to work under even more stringent thermal constraints (higher temperature), while remaining compliant with all the other constraints, especially the high voltage constraints. Indeed, the diodes and capacitor studied with their associated technology item are used in the high voltage part of the EPC. Therefore, architecture itself is not modified in the frame of this project.

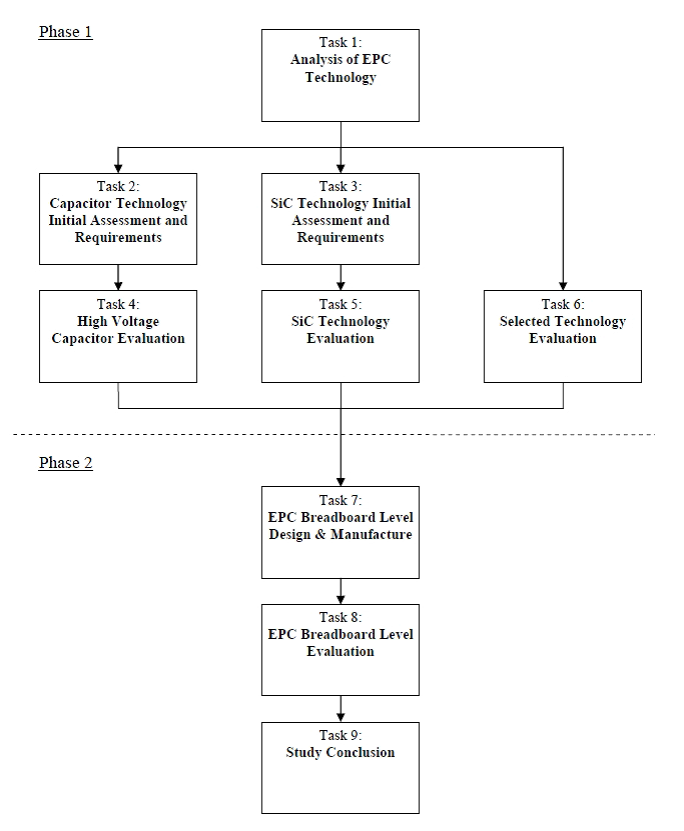

- Phase 1 – “Requirements, Technology Assessment and Component evaluation”

- This first phase covers the analysis, the development and the evaluation of the new technologies required in order to increase the high voltage board qualification voltage .

- Phase 2 – “EPC Breadboard and Final Presentation”

- This second phase concerns the manufacturing and testing of a representative EPC breadboard of a high voltage module for the evaluation of the selected new technologies.

The project is now achieved and the results are successful.

The selected alloy, capacitors and low CTE PCB are promising and deserve to be more deeply studied in order to implement them in future products.

Concerning SiC diode, the goal is partially reached but lessons have been learned. The main one is certainly about the radiation sensitivity of the SiC technology. It is a big issue that need to be solved before the implementation of Sic components in our equipment.

This issue will be deeply studied in a future project funded and managed by the European Commission (H2020), in collaboration with partners.