-

StatusCompleted

-

Status date2016-03-14

-

Activity Code4B.090

Nitrous Oxides Fuel Blend (NOFB) propellants are re-emerging and may be a candidate for the next generation propulsion system for Telecoms applications. In Europe there is little Experience in NOFB as alternative for hydrazine. The objective of the work is to obtain experience in propellant composition, handling, operating and integration of NOFB propulsion technology.

To reach the level of experience the following topics are addressed:

- propellant formulation and selection;

- propellant characteristics, compatibility and handling;

- propellant experimental performance data;

- system impact.

Within the activity, based on a solid set of requirements and a trade-off on various performance criteria, ethanol was chosen as fuel for the European NOFB. Miscibility and vapor pressure characteristics were determined and it was found that the miscibility of nitrous oxide and ethanol is limited to a maximum of 60% of the optimal (stoichiometric) value, resulting in a fuel rich propellant.

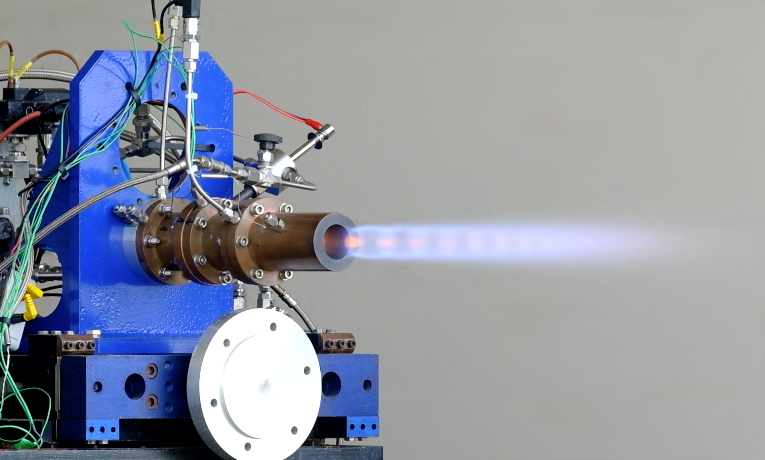

With this propellant, engine level tests were performed to investigate the basic combustion parameters such as flow properties, combustion stability and performance.

The obtained data on composition, miscibility, compatibility and performance was used to investigate the impact of changing the current state of the art satellite propulsion systems for a NOFB propulsion system.

Successful firing of a thruster with the selected NOFB as propellant at Airborne Engineering Ltd. facilities. (Credits to AEL Ltd.)

Safety is the main challenge within this project. Mixing of an oxidiser and fuel within its flammability limits is per definition hazardous. Developing a NOFB blend with excellent performance characteristics and manageable handling and safety characteristics is key to the success of this project.

The potential hazards of the NOFB mixture limits the engine testing to a test setup in which the NOFB will be mixed just before injection into the test engine. This, together with suitable safety measures such as flame arrestors, prevents a catastrophic event in case of a flash back.

NOFB propellant, if proven that the potential hazards with this propellant are manageable, offers the potential of bi-propellant performance with mono propellant system complexity. Nitrous oxide and the potential fuels that makes NOFB are all considered ‘green’ and the chance that the use of these components will be restricted by REACH legislation is negligible.

NOFB is in potential an excellent low cost and durable replacement for hydrazine and may strengthen the competiveness of European SatCom industry.

The beneficial features of NOFB that makes this propellant attractive for space propulsion systems are:

- Nitrous oxide and the potential fuels that make NOFB are all considered ‘green’ and the chance that the use of these components will be restricted by REACH legislation is negligible.

- The price of Nitrous oxide and the potential fuels that makes NOFB is low compared to the current storable propellants

- NOFB is self-pressurizing, no pressurization gas or pumping system is required

- The Isp out-performs that of hydrazine and approaches that of the current storable bi-propellant engines

A NOFB propellant will be defined, this propellant includes:

- Nitrous oxide

- Ethanol as a fuel

The work in the project plan is organised in four technical tasks being:

Task 1: Propellant definition

- Task 2: Engine testing

- Task 3: Propellant handling study

- Task 4: Sub-system Impact Assessment

The project deliverable reports are the following:

- Propellant Selection Study

- NOFB Propellant Formulation and preparation report

- Propellant handling report

- Engine test report

- Sub-system impact report

- Final report

In 2018 the activity was finalized by means of the delivery of the final report.

The kick-off of the project was on the 13th of November 2015. The selection was performed in 2016 as well the propellant handling study. In 2017 the engine firing test were performed and the concluding system impact study was executed.