-

StatusCompleted

-

Status date2016-07-05

-

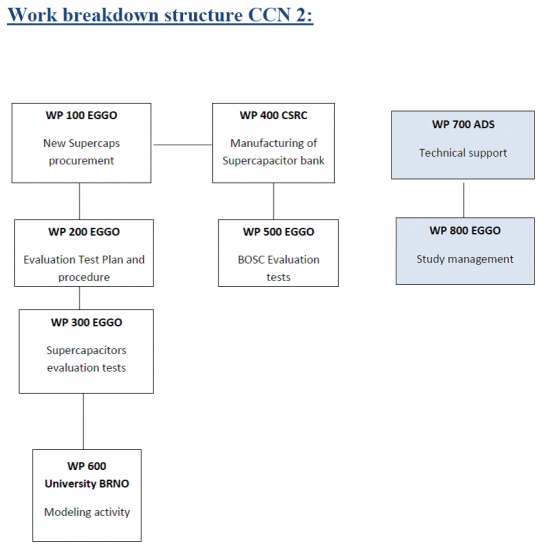

Activity Code4F.058

1/ The main technical objective is to evaluate current state of the art in commercial supercapacitor technologies suitable for space grade capacitor that can increase the specific energy density beyond 6Wh/kg.

Supercapacitors (also called ultracapacitors or electrochemical double layer capacitors) are suitable for high power applications. These devices are now available on commercial/high end commercial market and used in civil aircraft industry (Airbus A380,Boeing), in automotive industry, defence (radars) , telecommunication infrastructure (base stations) etc. Supercapacitors are based on an electrochemical reactions (energy is stored physically and not chemically as for a battery), their cycle life is very high (up to 1 million cycles). The current energy stored of commercially available supercapacitors is today relatively low up to 5Wh/kg. There are basically two types of the electrolyte- 1) lower Capacitance and lower ESR aqueous based or 2) higher capacitance, higher ESR polymer electrolyte based. The first type of the supercapacitors are more suitable for telecommunication application due to the lower ESR and higher frequency operation capability. The second, higher ESR types are closer to battery type of applications.

There are several Europeans manufacturers of supercapacitors but mainly interested in high volume production with rapidly evolving technologies that may not be suitable for space application.

2/ Other objective is to choose the most suitable type of Supercapacitor for producing of the Bank of Supercapacitors in two models suitable for Space applications.

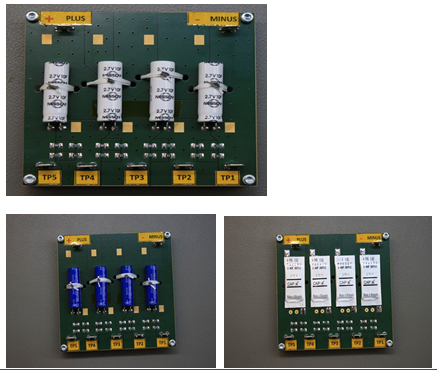

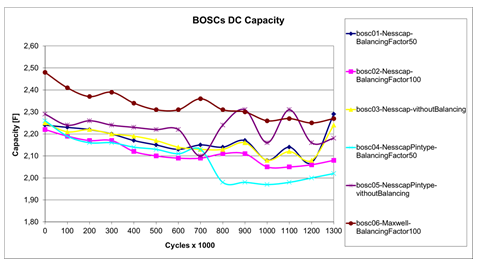

3/ This project was extended by a CCN2 with the aim to extend the evaluation of the original Supercapacitors in terms of suitability for space applications. Characterisation tests, environmental tests, life tests were carried out. Another activity was to evaluate new Supercapacitors models Maxwell BCAP0010 P270 and Nesscap EHSR 0010C0-002R7P Pintype, which is modified in terms of better hermeticity than the original Nesscap. This extended study also included a new BOSCs modification in 8 versions where 7 types are 4s1p modifications which means 4 cells connected in series on a PCB without housing and 1 pc of BOSC 15s2p made of 15 pairs of cells in series of new Nesscap Pintype also without housing. The Nesscap pintype cell showed an inferior performance as compared to the original Nesscap cells, possibly due to a suboptimal sealing. The Maxwell BCAP0010 showed a good performance and can be used as a viable backup for the Nesscap cells. The tests of the 4s1p BOSCs showed that a balancing system is needed for keeping the cells in a balanced state during the cycling. A balancing factor of 50 (ratio between balancing current and leakage current) seemed to be sufficient. The 15s2p BOSC, which was based on the Nesscap Pintype cell showed an inferior performance as the 15s2p BOSC based on the previous Nesscap cells.

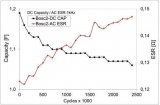

After 2.4 million cycles the BOSC showed a capacity fade of around 13% and a low internal resistance increase of 38%.

The manufactured 4s1p BOSCs were tested in a cycling life test at 45°C passing more than one million cycles.

CCN2 new BOSC modifications 4s1p

The manufactured 4s1p BOSCs were tested in a cycling life test at 45°C passing more than one million cycles.

4s1p BOSCs Capacitance progress in for different cells and balancing factor

100%