-

StatusCompleted

-

Status date2020-08-13

-

Activity Code5C.331

The objective is to identify the technology that offers the best potential to accomplish the realization of a SMA compatible fast locking connector for cable assemblies and establish a complete and self-consistent set of technical requirements for the development.

The targeted improvements are to achieve TRL level 5 and to get an increased layout density for payload equipment in the order of 20% together with up to 30% reduction in assembly, integration and testing (AIT) time of payloads.

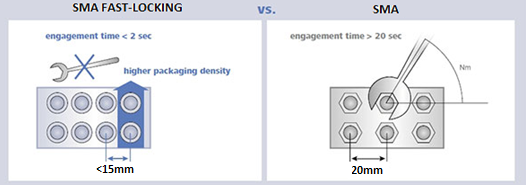

Today SMA connectors are tightened to a specific torque using a torque wrench by AIT operators during the integration phase. The need to have sufficient space to access these connectors and to use a torque wrench requires a specific area around the connectors to be reserved in the interface design. The challenge is to remove the need to use a wrench to increase freedom in the design of the equipment interfaces and locations.

The benefits of this SMA fast connector are:

- More speed to assembly due to Push-Pull mechanism (self-locking);

- higher packaging density, since tooling is not required;

- no requirement for torque spanner for high, defined contact force;

- higher contact force;

- excellent electrical characteristics (intermodulation, return loss, contact reliability);

- higher mating cycles;

- resistance to the stresses caused by a satellite launcher;

- resistance to use in space environment.

The Falcos Engineer Model already tested has demonstrated good electrical and mechanical characteristics suitable for use in space applications.

The material selected are fully compliant with ESCC advice with special attention to outgassing level.

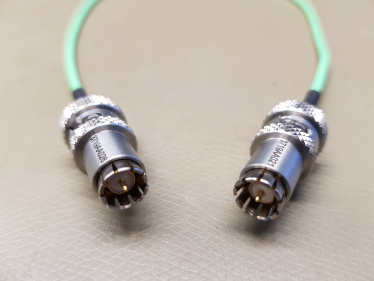

Dimensions: L 30 mm Ø 10 mm

Mass: 11g

Fast and self-locking coupling system with double security

Compatible with all SMA standard jack

The program lasted 18 months.

The prototype has reached a level of TRL5.

The following Milestones have been considered:

- PDR - Preliminary Design Review: T0 + 8 months

- TRR - Test Readiness Review: T0 + 12 months

- FR - Final Review: T0 + 18 months

Project completed. September 2018 - March 2020

The project is ready for improvement in order to reach a TRL8.