-

StatusCompleted

-

Status date2019-10-16

-

Activity Code5C.264

The main objective was to develop two SAW filters at S-band, using lossy filter design techniques, as SAW technology offers high Q-factors and compact size.

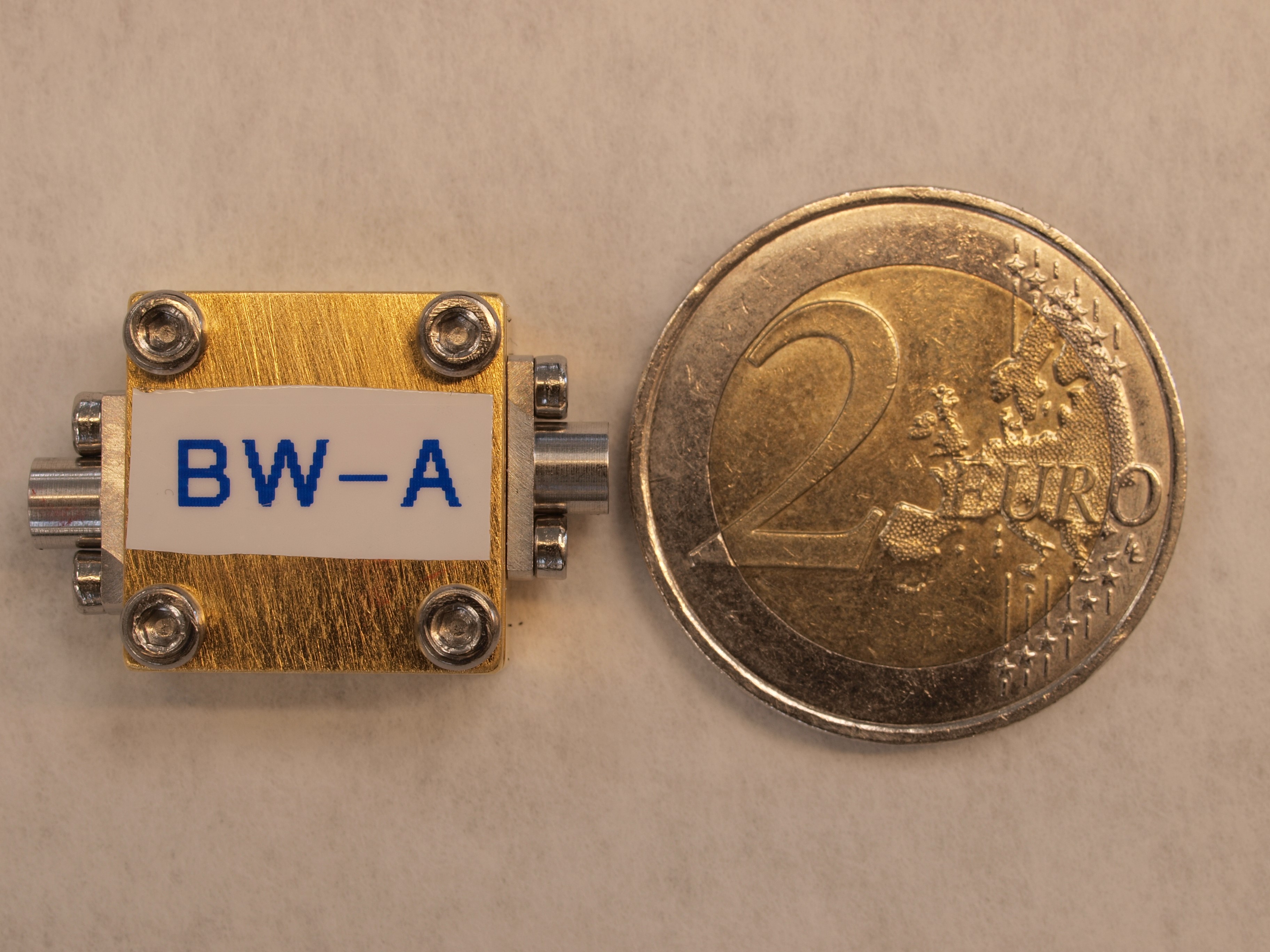

The produced filters show excellent performance (insertion loss, passband ripple and selectivity). The size of the filter assembled in package is about 150mm2 (15x10mm2) and has a weight of 0.9 gram.

The main challenge was to find a way to design lossy filter elements in the SAW structure in a way that was possible to implement. The task required development of advance mathematical modelling and simulation tools.

The excellent performance and small size open for many potential applications for the developed filter. For example, the filter can be used as IF filter in Kongsberg Space Electronics Command Receiver. Here the filter will replace the existing mechanical filter. The mass and size for the filter will be reduce with ~ 90%. Other applications are within pre- and post-processors for digital payloads. Due to the high quantity of filters in this application, the use of the developed filter technology will open for significant mass savings. Significant cost savings could also be achieved in many cases.

Two filter types were produced, named BW-A and BW-B, with the objective of reaching a 1 dB bandwidth of 40 and 100 MHz respectively. The filters were assembled in packages and measured in a test module fixture. The BW-A filter was produced on Lithium Tantalate, and resulted in a 44 MHz 1dB bandwidth, shape factor of 1.8 and an insertion loss of 5.5 dB. The BW-B filter was produced on Lithium Niobate to achieve the needed bandwidth, and resulted in 103 MHz 1dB bandwidth, shape factor of 1.8 and an insertion loss of 5.0 dB.

The study logic followed the tasks from statement of work. Each task was concluded by a dedicated review.

Task 1: Literature Review and Trade-offs

- Technology Review

Task 2: Preliminary Design and Technology Validation

- Preliminary Design Review

Task 3: Breadboard Design

- Design Review

Task 4 Breadboard Manufacturing

- Test Readiness Review

Task 5 Breadboard Testing

- Test Review Board

Task 6 Final Evaluation and Development Plan

- Final Review

The program is completed with successful Test Review Board and Final Review.