-

StatusCompleted

-

Status date2014-01-21

- to improve accommodation of such units on Communication Modules,

- to answer to the growth of spot quantity on Multimedia architecture.

The development goal of the project is to develop a LDLA including 2 RF chains. It shall also provide flexibility for the control of the TWT saturation output power which up to now is a fix point. For multi-beam mission with a large number of beams it also offer a very compact solution (save of footprint on the satellite panel).

The temperature range qualified is +65/-15°C

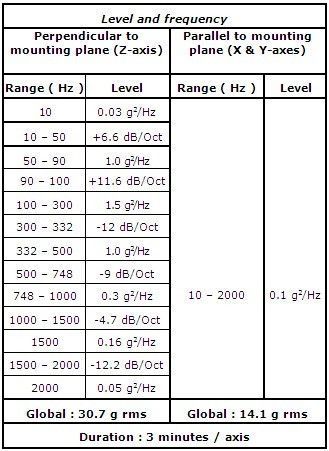

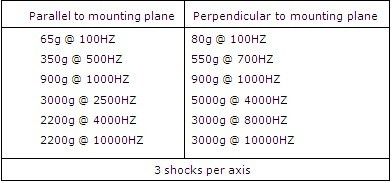

The random vibrations level qualified is:

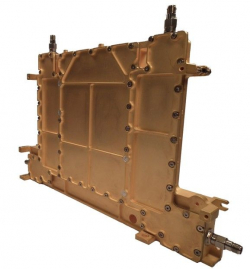

The EQM stacked dual LDLA has successfully passed the following qualifications tests.

The two RF chains are integrated independently in one mechanical structure. Each chain is composed of an amplifier module and a linearizer module. A unique TMTC card controls the 2 RF chains. The power supply is provided by the EPC.

The proposed development plan is divided in 2 batches: The first one is dedicated to the study of the TM/TC board, the development and the validation of the dual LDLA concept, supported by bread boarding activities, the second one is the formal qualification of the product, achieved with the manufacturing and test of an EQM LDLA dual.