-

StatusCompleted

-

Status date2011-12-13

-

Activity Code5B.064

The development of Ka-band reflectors represents one step forward with respect to more conventional designs (i.e. C/ Ku band reflectors). In practical terms, it implies a certain number of modifications to be achieved better performances in terms of:

- Thermo-mechanical stability,

- Radiating surface accuracy,

- Radiating surface specularity.

This last consideration is important in the KaSat mission due to the significant number and size of the reflectors, with two metallised reflectors in each side of the satellite, which globally represents an important reflecting surface (18-20m2) close to the body of the satellite also equipped with OSR (optical solar reflectors).

This effect also called “double Sun”, has been also identified in previous missions with double deployment side wall reflectors (two main reflectors in each side of the spacecraft) with a smaller influence in the overall thermal control of the reflectors.

To correctly validate this effect, it is required to perform a certain number of thermal analyses to predict the thermal environment that the reflectors should withstand. These thermal analyses are included within the scope of the present study phase.

The objective of this study phase is to pave the way for the detailed analysis manufacturing and testing of the first PFM Ka sat reflector which will be faced on the next full proposal phase.

Objectives within this study phase are:

- Analysis of Ka Sat reflector requirements,

- Thermo mechanical preliminary design and analysis,

- Manufacturing and test of development test samples.

Related with the development samples, the main areas of interest are related with:

- High temperature adhesive (FM-300) characterization, aimed to enlarge the temperature range of the EADS CASA standard used one (BSL 312),

- Mechanical joint characterization , including a complete set of mechanical connections of the different backing structure / dish joint,

- Sunshield baseline material and fixation validation concepts, needed to select a material compatible with the specularity requirements and the way to fix the sunshield to the dish due to the allowable volume.

In accordance with the project plan, the main key issues are:

- To derive the A- Values mechanical properties of the CFRP material after thermal cycling,

- To have a complete set of the reflector back structure mechanical connections tested,

- Perform a study of the specularity requirements , select the best method to measure it, and based on this to decide which surface is the best one to avoid the “ double sun “ effect onto the satellite walls.

To select this type of surface and evaluate its feasibility to face the qualification program in the frame of the full proposal phase.

- To have all the initial required data to face the detailed design of this type of big (2,7 m Ø ) metallized Ka band reflectors,

- To ensure that with the above inputs the RMS of the reflector will be within the required values,

- To select a non specular first reflective surface (sunshield), that will be qualified within the next phase.

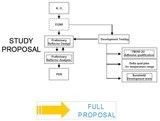

The work flow logic for this phase can be summarized below:

Outputs of this study phase will serve the full proposal phase, which is to be covered in the frame of another contract.

The project plan in the form of the proposed work breakdown structure can be found below.

WP-1000 Management and QA

This WP collects all the normal management and QA activities within the program.

WP-1100 Analysis of requirements

This WP analyzes the different requirements and collects them under a reflector specification, that will be used later to perform the preliminary reflector thermo-mechanical analysis.

WP-1200 Thermo-mechanical , preliminary design and Analysis

Based on the previous WP, a preliminary reflector design and thermo-mechanical analysis is made, the analysis takes into account the conclusions of the development samples obtained from WP-1300.

WP-1300 Development test samples

This WP collects the characterization of reflector shell and back structure skins to core adhesive, as well as junctions of the main representative back structure joints, as part of the study the selection of a non specular material surface for the sunshield is selected , in order to be faced on the next program phase.

The program has been completed.

A final presentation was held at ESA ESTEC on march 27th. All objectives within this phase have been achieved, ready to start the full proposal phase.

All deliverables as per contract conditions were provided.