-

StatusCompleted

-

Status date2021-11-10

-

Activity Code4D.071

The final objective of the project is to identify and to develop a simplified RF frequency converter line-up capable to be integrated in a single MMIC (SCFC) and, at the same time, to provide all the main functionalities included in the more complex conventional equipment, required to meet the radical changes that are involving the future satellites for telecommunications, in terms of architectures and costs, mainly for LEO and MEO constellations.

To hit this target, the Single Chip Frequency Converters have the following characteristics:

- Integrate the three main functionalities of a classical frequency converter line-up (LNA, Broadband Mixer and Power Amplifier) and increase of about 1 order of degree the integration density with respect to the today’s space qualified frequency converters, often based on very complex and expensive hybrid modules;

- Be compatible with different frequency schemes;

- Provide the gain adjustment facility;

- Provide the same performances of consolidated classical frequency converters.

Looking at the conversion schemes required by the main segments, two different MMICs are developed and tested:

- A Ka/Ka band Single Chip Frequency Converter

- A Ku/Ku band Single Chip Frequency Converter

Furthermore, the design of a full Down Converter line-up (DoCon) including the output filter for frequency plan customization is performed at both Ku and Ka bands and a Breadboard based on one chain DoCon is developed and tested.

The main challenges addressed by the project are:

- The integration in a single 25mm2 MMIC, based on European technology, of all the functions actually used in the conventional converters’ RF chain: RF and IF gain amplifier, mixer core, LO buffer, RF power amplifier, variable gain and attenuation blocks.

- The implementation, within the same chip, of the advanced features required by the future applications: gain adjustment in the range of 20 dB, full compensation of the gain variation over temperature.

- The implementation of broadband conversion ranges, with quite high relative bandwidth for RF, LO and IF components.

- To integrate 4-channel Downconverter lin-up in a single hybrid block.

New telecom constellations are calling for radical changes in the way a telecom satellite is designed, leading to significant miniaturisation and increase in capabilities of small satellites. Frequency Converters, basic building blocks of RF equipment supporting satellite communications, providing frequency translation of the input signal to a desired output frequency, have to be well within this goal. Conventional frequency converters are fairly complex equipment that are designed to cope with a very wide range of requirements, complying with different platforms, multiple frequency conversion schemes, various link gains, etc. which inevitably translate into high cost. An improvement in terms of mass and cost can be reached by the use of the developed SCFC, integrating a simplified frequency translation chain into a single chip providing gain adjustment before and after a broadband mixer capable of supporting various frequency translation schemes.

This new technology is profitable for future LEO and MEO constellations, with an increase of integration density by a factor of 10 in comparison to today's space qualified frequency converters, in a context where mass and volume requirements are more stringent than for GEO satellites.

In addition to the clear improvement in terms of system dimensions and complexity, the developed SCFC allows an high level of flexibility providing the following key features:

- Broadband conversion range: various frequency conversion schemes can be addressed by the application of specific filter at the output of the chip, allowing the customization for different applications.

- Selection of the optimum LO signal frequency, within a quite wide range, for harmonics and spurs rejection.

- Gain adjustment in the range [40 - 20] dB by 1-dB step, allowing the optimization of the full line-up on the basis of the specific application. The Gain setting by means of 2-levels control signals.

- Full Gain compensation over temperature by means of a specific control voltage, allowing a continuous gain variation in a range of about 7 dB.

- Good performances in terms of linearity and spurs rejection.

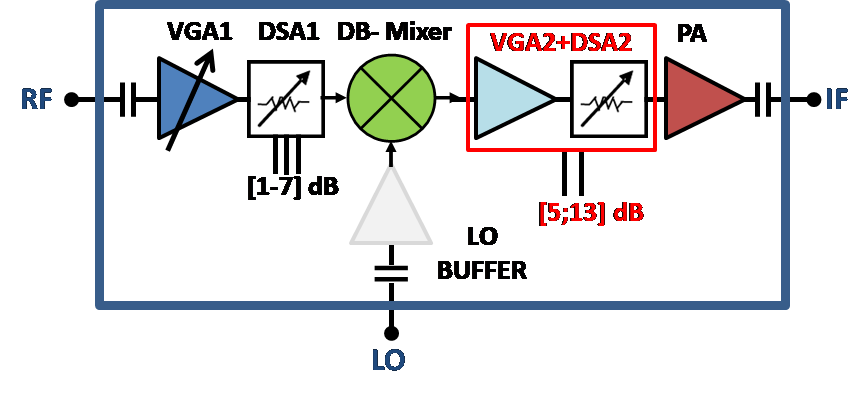

The optimum architecture for the SCFC MMIC is shown in the following figure. The different elementary blocks, and related gain and attenuations, have been properly distributed and positioned over the chain for the best trade-off between Gain, Linearity, LO harmonic rejection and Noise. Here below the main characteristics of the different functions highlighted in the picture:

- VGA1: RF Variable Gain Amplifier that provides the first stage of Gain and its continuous gain control is implemented to compensate the overall gain variation over temperature.

- DS1: RF 3-bit Digital Step Attenuator that performs the first steps of the SCFC gain attenuation from 0 dB to 7 dB, out of the total variation of 20 dB.

- DB Mixer: Broadband Mixer Core and LO Buffer to performs the frequency conversion according to the specific frequency synthesis.

- VGA2+DSA2: IF Gain stage and 2-bit Digital Step Attenuator, at the output of the Mixer, provide gain and perform the remaining 13 dB of gain variation.

- MPA: IF Medium Power Amplifier that provides the remaining gain step and the required linearity levels.

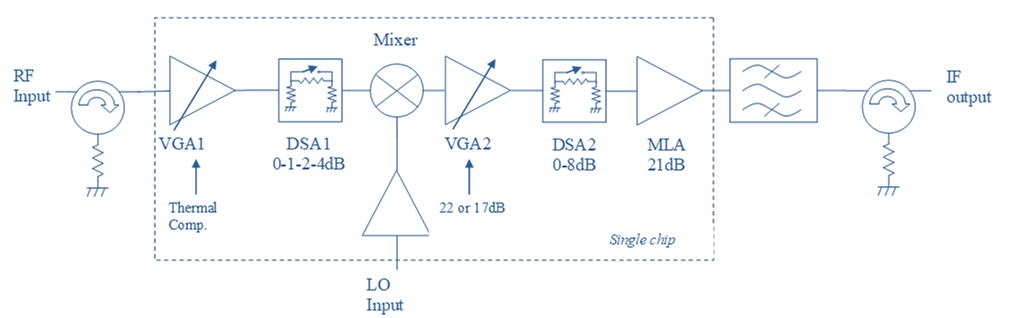

The architecture of the full Converter (DoCon), shown in figure below, is based on the SCFC cascaded after an isolator at the RF port and before the IF Filter and an output isolator.

The project is developed on the basis of the following tasks

- Task 1: Identification of best architectures, for SCFC and DoCon, and definition of the Baseline Specifications;

- Task 2: Critical Elements and single functionalities Design and Test

- Task 3: SCFC and RF Line-up Detailed Design

- Task 4: Manufacturing Integration & Test

and though the following Milestones:

- Preliminary Design Review

- Critical Design Review

- BreadBoard Test Review

- Detailed Design Review

- Final Review.

Project has been completed. The SCFCs, both Ku- and Ka-band, and the breadboard for DoCon demonstrator have been manufactured and tested with results very close to the requirements.