In early July, an innovative Deployable Panel Radiator (DPR) underwent mechanical tests, both sine vibration and acoustic, at ESA's test facility at ESTEC in Noordwijk, the Netherlands. After it undergoes a full thermal performance validation campaign in Euro Heat Pipe’s Thermal Vacuum Chamber, the Qualification Model should be fully certified for flight by November 2016. The new DPR, a premiere in Europe, has been developed with the extensive support of ESA through the ARTES Large Platform Mission (formerly Alphabus) by prime contractor Airbus Defense & Space.

Airbus DS has announced that a DPR unit will be incorporated into its new Eurostar Neo product line catalog. Eurostar Neo is part of the ARTES Next Generation Platform element, the ESA program to develop and qualify two commercially competitive satellite product lines in the 3 to 6 tons launch mass range by the end of the decade.

Thermal dissipation has become a significant challenge for satellite manufacturers, owing to the ever-increasing payload performance that operators require for modern telecoms missions. Traditionally the fixed passive radiators on the north and south panels of telecoms spacecraft were sufficient to radiate heat into space and keep spacecraft from overheating. But for such missions as the new generation of Very High Throughput Satellites, generating on the order of 25 kW of power, they are no longer adequate.

Thermal dissipation has become a significant challenge for satellite manufacturers, owing to the ever-increasing payload performance that operators require for modern telecoms missions. Traditionally the fixed passive radiators on the north and south panels of telecoms spacecraft were sufficient to radiate heat into space and keep spacecraft from overheating. But for such missions as the new generation of Very High Throughput Satellites, generating on the order of 25 kW of power, they are no longer adequate.

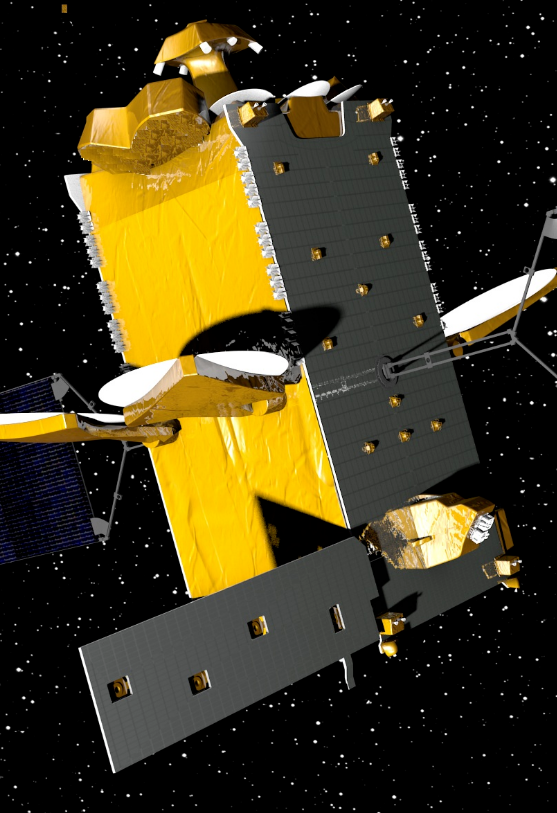

The Deployable Panel Radiator will provide additional radiating capability for such highly dissipative payloads. Up to two DPRs can be accommodated on each satellite, with a maximum dissipation of 2.4 kW per unit in the Alphabus configuration.

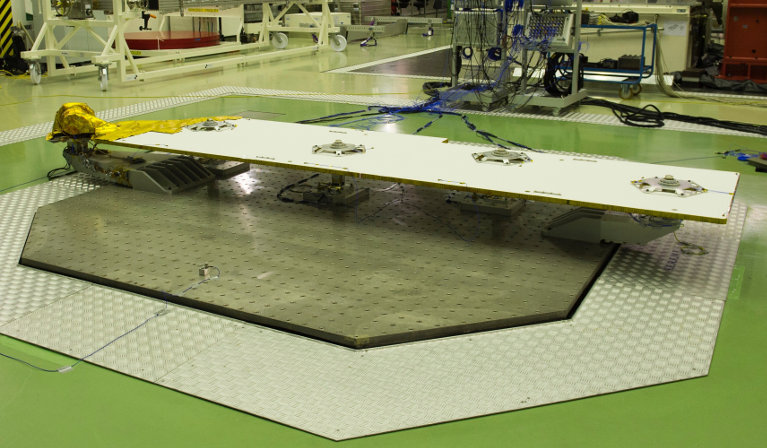

The DPR’s most innovative aspect is its passive circulation system, which allows for efficient cooling of the payload thanks to two-phase loop heat pipes. Heat is transported by gaseous ammonia from evaporators fixed on the payload heat pipes to condensers embedded inside the large radiator panel (4m x 1m). After condensation, ammonia returns in liquid form to the evaporators thanks to capillary mesh acting as a passive pump.

During launch, each DPR is stowed against the spacecraft body. Once in orbit, it is deployed by means of a single-axis mechanism which incorporates flexible piping required for the cooling fluid.

The new DPR represents a joint effort by leading European space engineering firms. As prime, Airbus DS Toulouse provides the systems engineering and design authority as well as overall project management for the European-wide industrial organisation.

Its long-time partner Euro Heat Pipe, an innovative Belgian SME, is responsible for manufacturing, assembly, integration and testing of the DPR system and its three main building blocks – evaporators, panel & deployment mechanism. The latter uses an ITAR-free Rotary Actuator recently developed and qualified by Sener (Spain) thanks to ESA & Airbus DS support. The complex Mechanical Ground Support Equipment supporting the assembly, handling, transport and testing of the DPR with its large dimensions are designed and manufactured by Gradel (Luxembourg).

"The future of our DPR product line now looks promising with a good alignment between mission requirements and availability of flight-qualified building blocks ready to be reused in the future," says François Jacquemart, Deployable Radiator Product Manager at Airbus DS.

"The Deployable Panel Radiator represents an impressive technological achievement for the European space industry,” says Philippe Sivac, ESA's Project Manager for Eurostar Neo. “In particular the flexible piping required for the deployment of the cooling fluid line required real ingenuity.”

“All these activities have been made possible by ESA Member States' support for the ARTES Large Platform Mission programme,” he adds.

Photos credit: ESA/G.Porter