-

StatusCompleted

-

Status date2021-01-08

-

Activity Code5B.196

The objectives of this project are the following:

- Develop a waveguide-based solution for a transmit (Tx) direct radiating array (DRA) operating with dual-circular polarization in Ku-band based on additive manufacturing (AM).

- To achieve state-of-the-art RF performance of the antenna array while having a competitive mass budget compared to existing PCB-based solutions.

- To manufacture and test all the critical elements that compose the passive part of such an active antenna, based on AM.

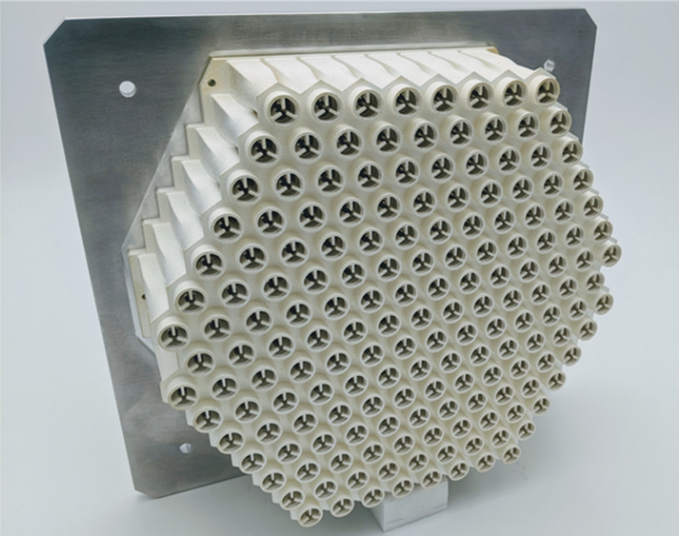

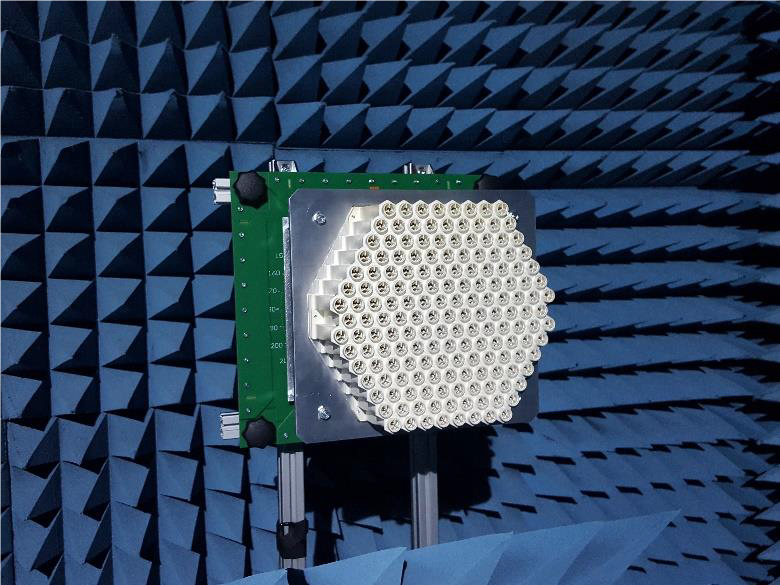

The biggest challenge of this activity is the manufacturing of a monolithic antenna array using additive manufacturing (AM). Despite the small inter-element distance on the array, the possibility to obtain a dual-circularly polarized passive antenna aperture, fed with GPPO connectors, is demonstrated.

The developed product has considerable advantages over other competitive products:

- Reduced assembly effort: one monolithic AM part together with one machined metal plate used for mounting the connectors.

- Reduced weight: the final breadboard weights only 3.5 kg, resulting in a weight of only 21g per (dual-polarized) radiating element.

- Improved RF performance: the developed product has reduced insertion losses (with respect to arrays in PCB technology) and grating-lobe free performance in the entire FoV by design, due to the mini-horn concept used for the radiating elements.

- Dual-circular polarization: dual circular polarization enabled despite the low-profile design of the antenna array.

Clearly, the most important feature of the developed product is the use of AM as an enabling technology to achieve a series of objectives, ranging from mass and volume reduction to RF performance enhancement.

AM provides the necessary design flexibility to achieve the aforementioned objectives by cleverly designing antenna arrays dedicated to this technology. This means that the entire passive aperture can be fabricated without the need for any support structures inside the 3D printer (hence, significantly reducing the post-treatment steps of the additive manufacturing). This is an essential step towards the industrialization of the production of parts based on AM technologies. Finally, the RF performance is enhanced by metal-plating the array with a special electroless process developed by SWISSto12, leading to improved surface roughness and, therefore, reduced insertion losses.

The system architecture is relatively straightforward. GPPO connectors are used to feed two singe-ridged waveguides per radiating element. The ridged waveguides are then connected to a septum polarizer that generates the two circular polarizations. The (Tx) radiating element is a tri-ridged circular mini-horn. A waveguide filter able to reject the Rx Ku-band and several radio-astronomy bands up to 24 GHz is demonstrated and de-risked on a separate breadboard.

The project has two phases, one focused on the design and one of the manufacturing and testing of the breadboard. First, a Requirements Review meeting helps to select and freeze the requirements for the antenna design. Then, a detailed RF and mechanical design as well as the detailed test plan for the breadboard are developed and consolidated on the Design Review meeting. The success of the manufacturing process is then evaluated during the Test Readiness Review meeting, before the execution of the detailed test plan. All the obtained results are carefully reviewed during a Test Review Board meeting and further actions for the investigation and analysis of the results are decided. The final work package serves a dual purpose: (a) analysing the obtained results and identifying potential improvements after critically evaluating the achieved performances and (b) thinking about the future product development steps, including a roadmap and a market status evaluation. All these objectives are discussed during the Final Review meeting with the Agency.

The project is completed by successfully manufacturing and testing an antenna array breadboard with 167 dual-polarized Tx radiating elements in Ku-band.