-

StatusCompleted

-

Status date2018-11-06

-

Activity Code5B.175

In order to achieve the high production rates associated with satellite constellation programs, traditional handcraft processes need to be changed so as to be more in line with the automotive and aviation standards.

MDA will be focusing on the design, fabrication and test of steerable high gain Ka-band antennas and fixed beam Ku-band antennas suited to provide earth coverage from LEO.

Because of the quantities involved, the design for manufacturing effort is taken to the next level. The number of labour hours associated with antenna assembly needs to be reduced significantly from our standard constellation antenna production flow.

The main advantage of this solution is that the antenna production cycle from piece part receiving to final assembly shipping is completed in less than one week. It is using large volume fabrication techniques and commercial parts adapted to further reduce cost.

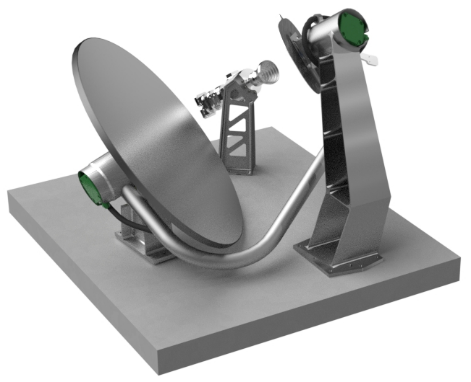

The Steerable Ka antenna is an Elevation over Cross-Elevation gimbal antenna having no key hole within the earth coverage The geometry implements a fixed feed configuration that entirely eliminated the need for rotary joints. The main reflector is illuminated by the image of a feed horn reflected by a flat superelliptical splash plate.

The Fixed Ku antenna solution selectedis a direct radiating passive array generating multiple fixed beams over the visible earth. The antenna uses a beam forming network to feed the 2 polarizations of the metallic radiators.

See product features

The initial phase of the project focused on finalizing the design of the steerable and fixed antennas. During the design phase, breadboard models will be fabricated and tested to verify key assumptions and design robustness with regards to manufacturing variability.

Following those verifications and trade-offs, engineering model of each antenna were built and CDR was held. Throughout those previous phases, design for manufacturing was driving piece part manufacturing process and product assembly. Automated RF test system and in-line measurement systems were developed to ensure good manufacturing readiness.

To complete the ARTES program, a qualification model (QM) of each antenna was manufactured and successfully tested to verify compliance to all environmental and performance requirements.

The development program is successfully completed. The qualified products and assembly line are now in use for an actual constellation program.