-

StatusOngoing

-

Status date2024-03-25

-

Activity Code4B.139

The primary objective of this project was to investigate options to improve the demise behaviour of a composite overwrapped pressure vessel (COPV). Those are ranging from basic material properties, material configurations, the influence of the aspect ratio, and shape options to possible add-ons or modifiers. The thermogravimetric characterization of typical COPV materials shall provide a solid ground for a baseline re-entry simulation which is also the benchmark for later improvements. Specific demise parameters for the most promising improvement solution shall be gathered in a plasma wind tunnel test campaign. The demise model of the simulation environment shall be extended to integrate these parameters and allow for a re-entry simulation of a demise-improved tank system. Furthermore, the influence of these improvements or modifications to the COPV shall be studied with regards to cost, complexity, performance, and safety implications.

The consolidated project requirements dictate a metallic liner and an overwrap from high strength fibers to be able to meet the leakage and mass criteria. Since titanium as a liner material and aramidic/kevlar fibers for the overwrap would make matters even worse, the only option are an aluminium liner and carbon-fiber reinforcement. As a safety and fracture critical item, any modification to a COPV requires extensive investigation and testing to become validated.

The benefits of a demise improved COPV range from eased requirements for spacecraft design, a reduction, or even complete cancellation of end of life (EOL) measures to greatly reduced insurance provisions. Ideally, the properties of our demise improved COPV remain largely equal to those of our standard product lines.

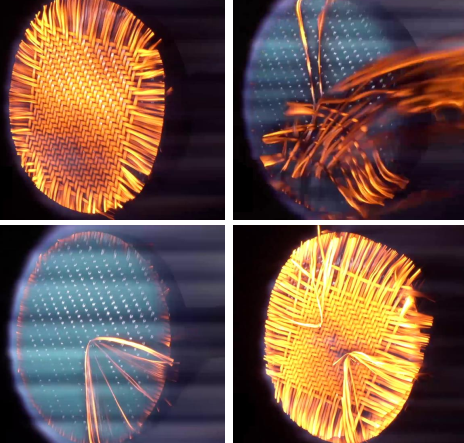

Type 3 COPV with an aluminium liner geared towards an improved demise behaviour.

The project spans over three project phases. The first phase includes a standard material characterization and the baseline re-entry simulation. In the second phase, demise improvement modifications shall be investigated and tested for their demise behaviour. In the third phase, the selected improvement modifications shall be evaluated for impact on product properties and compared to the baseline in an improved re-entry simulation.

The development project has shown that unexpected setbacks can lead to a rethink of the plan and a return to the basic investigations. It also highlighted, that more investigations are necessary to bring the D4D strategy for COPVs to the next level. However, it is believed that with the gained knowhow in matrix systems in combination with the innovative strip tape concept, there is an optimistic way forward in developing a demisable tank in the near future