-

StatusCompleted

-

Status date2019-01-08

-

Activity Code4E.052

The main objective consists in improving the European manufacturing capability for high voltage (>6kV) and high temperature applications (Tmax : 180°C).

The targeted improvements include enhanced thermal stability and insulation properties of adhesive potting for high voltage applications. In addition, a specific attention has been given to EU sourced materials for development.

The current Technology Readiness Level (TRL) for new materials is TRL2. Activities performed in this project targeted to improve the TRL in order to reach TRL4.

The technical goals are:

- The materials we searched and tested shall fit to several criteria.

- The main technical issue is the high voltage insulation: the material shall demonstrate above 6kV operation with no loss of performance.

- The mission lifetime is also a key. For Telecom satellite, a 15 years in-orbit operation is required.

- The temperature range is a crucial criterion. We targeted a class H resin (e.g. a resin with a range -55°C to +180°C).

The main challenge is to succeed in finding a material suitable with all our criteria:

- The material shall be compatible with thermal requirements (ideally class H) and electrical insulating performances at high voltage.

- The material shall be suitable with our applications requirements and with our processes (pot life, viscosity, implementation, etc.)

- The manufacturer of the material shall not be submitted to material exportation license limitations (ex. ITAR or patents).

- The material shall not be radiation sensitive: the criticality of the selected materials regarding radiations environment aspects has been assessed during the materials trade-off.

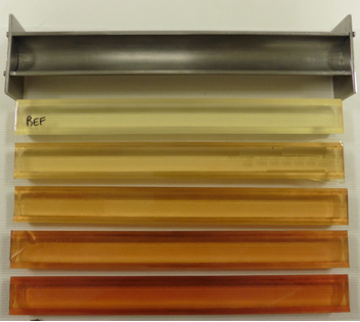

The state of the art and the materials trade off led to identify a broad range of commercial resins that were evaluated for their suitability for replacing our current resin set as a reference in this study.

The complete tests sequences performed throughout this project lead to identify a resin suitable for our requirements and processes.

The Technology Readiness Level (TRL) improvement was also an objective. It has been targeted to improve the TRL for these new materials from TRL2 to TRL4. This target has also been reached; the selected material passed the validation in laboratory environment.

The objectives of this project were ambitious but we succeeded to identify a class H material that fulfills our requirements and processes except the sourcing location. Even if the European sourcing was a strong criterion, the technical performances of the US selected resin are better than the ones EU candidates. This is the reason why we finally selected a material from a US source.

The main product features are:

- The material is Class H (up to +180°C).

- Electrically insulating at high voltage (6kV).

- The material properties are convenient for potting and impregnation processes.

- The material is not concerned by REACH legislation.

The architecture is not an issue in this project because we dealt with a material and its implementation and we did not design a specific product.

Nevertheless, the assessment of the material performances has been undertaken through samples and breadboards.

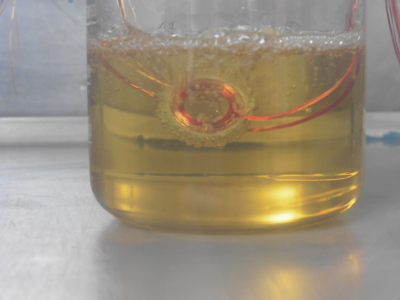

We designed several types of samples:

- Very simple ones to assess the properties of several material candidates and the behaviour regarding ageing test.

- Small samples to assess the suitability of several material candidates to our processes

- A breadboard representative of one specific application to assess the behaviour of the resin selected in a relevant environmental exposure.

This project has been divided in 9 tasks:

- Task 1: Critical review of requirements and applications

- Task 2: Review of the state of the art material and processes

- Task 3: materials and process trade off

- Task 4: Manufacturing, design and test plan

- Task 5: Sample Manufacturing

- Task 6: Sample Testing

- Task 7: Breadboard manufacture

- Task 8: Breadboard testing

- Task 9: Evaluation and reporting

The project is completed.

The goals of the contract have been reached.

This project permits to identify a material that seems suitable with all our requirements (at material and at processes levels).

The Technology Readiness Level (TRL) has been improved: TRL4 has been reached as targeted at the beginning of the project.

This project has lead TAS-B to acquire extensive knowledge about high voltage and high temperature potting materials.