-

StatusCompleted

-

Status date2015-12-09

The HighLIGHT SAT is a new large area Solar Array Tester (SAT) for measuring the electrical performances (IV curve) of triple-junction (3J) solar arrays of up to 10m2 at ground testing level (EGSE). The goal of this project is to provide a state-of-the-art reference solar simulator equipment for satellite primes, solar array manufacturers, space institutes and solar array testing laboratories.

The development is based on a first generation system and meets the requirements of the European space community.

The main targets are the following:

- Illuminated area for standard arrays of up to 4 m x 2.5 m;

- Reduced measurement distance from lamp to device under test to optimize the footprint, to best fit in test environment layout;

- Flexible concept (two configurations: large and small) in order to optimize operations;

- Class A non-uniformity according to ECSS-E-ST-20-08C: ≤ 2.0% as measured with each component cell of the 3J device;

- A new generation measurement platform and controlling software that allows determining very accurately the electrical characteristics of the array, simultaneous acquisition of the irradiances as seen by the three component cells, automatic and fast calibration process of the light source, and simple and user-friendly operation of the whole system.

This multisource solar simulator is composed of three synchronized light sources which are independently adjusted to precisely balance the spectral content in each of the three junction ranges. The target for the light calibration is ≤ ± 1% for each component cell (measured Isc compared to reference Isc).

In addition, the system is designed to be compatible with future 4J developments.

The key challenges of such development are the following:

- Reducing the footprint of the system, and in particular the distance from the light source to the device under test, while keeping a high quality of light regarding spectral content and uniformity on the whole test area (up to 10m2)

- Designing a system that can automatically calibrate the spectral content of the light in each of the three wavelength ranges corresponding to each junction of the 3J device to measure

Therefore, the optical light source as well as the electrical measurement and control are the main parts of this development.

The HighLIGHT SAT equipment is a state-of-the-art testing system for large area solar arrays. Its development has included the 30-years’ experience of Pasan in designing high-tech solar simulator for PV panels with the current requirements from the space industry and space agencies. As a result, this modern equipment surpasses all other similar products on this market.

The main advantages of this product are:

- Up-to-date industry standard: high quality multi-source solar simulator, latest generation electronic load and control software

- High accuracy of measurements

- Long pulse duration of 6ms and up to 10ms (real-time regulation), reducing the impact on measurement of the cells capacitance

- Lower footprint, available in two configurations

- Ease of use, optimize operation costs for calibration (by reducing typically the time from 30 to 5 minutes), measurement, maintenance

- Sustainable product with a highly qualified stable, robust and maintainable system over long period (> 10 years)

- System designed to be compatible with future 4J, 5J and 6J developments

SYSTEM ARCHITECTURE

The HighLIGHT SAT 3J is a turnkey system composed of the following elements:

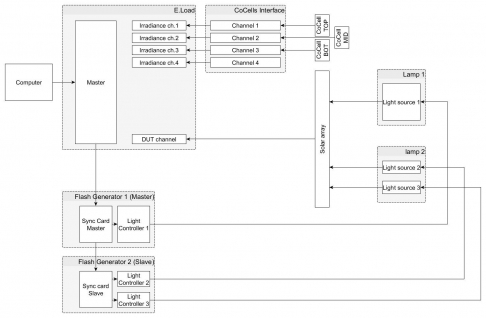

- A solar simulator (light source) including two flash generators and two flash boxes, which generate a pulse of calibrated light. The flash generators provide the necessary power supply and regulate the flash to keep constant irradiation conditions during the whole IV curve measurement. One flash box corresponds to the first light source (4 Xenon tubes), while the other includes the second and third light sources (2 Xenon tubes each). Each light source is distinct by its spectral filter which let go through a specific part of the solar spectrum, as well as by its nominal irradiance level. Each light source irradiance level is adjusted to fine-tune the spectral content on the test area according to the reference CoCells.

- The electronic load (IV tracer) scans the device under test (DuT) response on the full current-voltage (IV) curve during the light pulse. An amplifier interface is added to connect the non-shunted CoCells. The three CoCells are measured simultaneously.

- The advanced operating and measurement software includes an automatic and fast calibration process, as well as various measurement methods (including solutions de test capacitive DuT).

The HighLIGHT SAT system has two possible configurations:

|

|

Large configuration |

Small configuration |

|

Optical length* |

8 m |

5 m |

|

Illuminated area |

4 m x 2.5 m |

2.6 m x 1.6 m |

* Distance from the light source to the device under test

Compared to the first generation system, the distance has been reduced by 40% while the test surface has been increased by more than 25% (in particular for the large configuration).

For both configurations, the characteristics of the light source (AM0, 1.367 kW/m2) on the whole test area are the following:

|

Non-uniformity |

≤ 2.0 % |

as measured with each CoCell* |

|

Spectral match** |

≤ ±1.0% |

on each spectral band of each CoCell |

|

Pulse duration |

6 ms |

multi-flash meas. is also available |

|

Temporal instability of irradiance |

< 1.0 % |

real-time regulated pulse |

* CoCell = component cell; the three CoCell’s represent each of the three junctions of the 3J device

** Spectral match: deviation on Isc (short-circuit current) for each three CoCells, as compared to reference values

The solar simulator is composed of three light sources which are independently controlled. Each light source is made of the same Xenon tubes, but includes a different specific filtering and provides also a specific nominal intensity level. Each light source illuminates the whole test area.

Thanks to an advanced software that controls the system, the spectral content of the light on the target plane is calibrated with a set of CoCells (SWS) so that the measured short-circuit current (Isc) of each CoCell is within 1% of its reference value.

As a result, very accurate current-voltage (IV) curves and resulting parameters (Isc, Voc, Pmax, etc.) are obtained thanks to this advanced testing system.

The HighLIGHT SAT project started in early 2014. After the Kick-Off, two PDR meetings were used to review the design of the light source and of the various electronic parts before the CDR. Then the system was built and successfully tested during the FAT. The Final Review was successfully achieved in October 2015

The project is finished and has led to a complete product. The final acceptance test (FAT) of the system was successfully conducted. The results of the FAT were clearly within the expected specifications.

The HighLIGHT SAT 3J equipment is now available for space industry and institutes.