-

StatusCompleted

-

Status date2023-12-19

-

Activity Code5C.281

The objective of these projected 24 months activities is to industrialize, manufacture and qualify the compact, lightweight, low-cost and Low Noise Master Oscillators (LNMO), which has been developed in the frame of an ARTES 5.1 project, contract N°4200023116, by testing 16 Engineering Qualification Models (EQM) at 5MHz, 10MHz, 20MHz and 40MHz. To cover the whole frequency range only one crystal holder has been used (HC37), instead of 3 initially planned (HC40, HC37 and HC35).

These equipments shall be free of ITAR license control for use in worldwide space programs.

The key issues addressed in LNMO project are:

-

Reach phase noise requirements from 1Hz to 100kHz over the whole frequency range (5MHz to 40MHz)

-

Find solutions using ITAR free parts.

-

Validate several crystal suppliers with at least one European.

-

Cost reduction to gain market share

The expected benefits brought by LNMO project are:

-

An available qualified European ITAR free solution

-

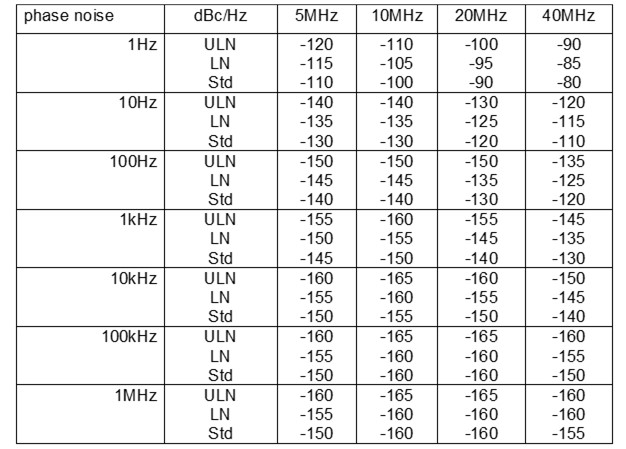

An improvement of phase noise behavior, better than current competitors’ solutions (see target in dBc/Hz):

-

Consumption, size and weight reduction

-

A design 100% compliant to the identified customers requirements; none from the identified competitors is compliant at 100%.

Key Features

-

Very small mass and volume

-

Low noise

-

Low temperature sensitivity

-

Fast warm-up

-

Wide operating temperature

-

Pre-adjusted frequency and/or voltage controlled.

-

Frequency Range: 5MHz to 40MHz

-

Supply voltage:12V or 15V

-

Low g sensitivity

Applications

-

Transponder

-

Radar

-

FGU

-

Synthesizer

-

Converters

-

GPS Receiver

-

Navigation

-

OBC

LNMO current design

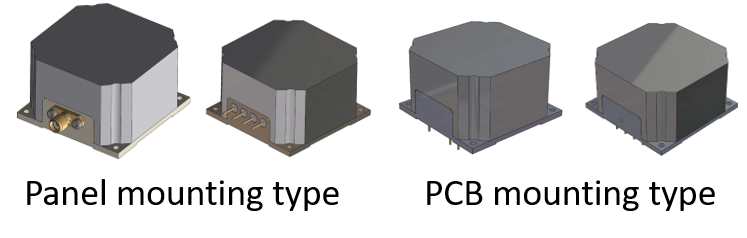

Size: 50x50x30mm

Weight: 100 - 110 grams (depends on pin configuration)

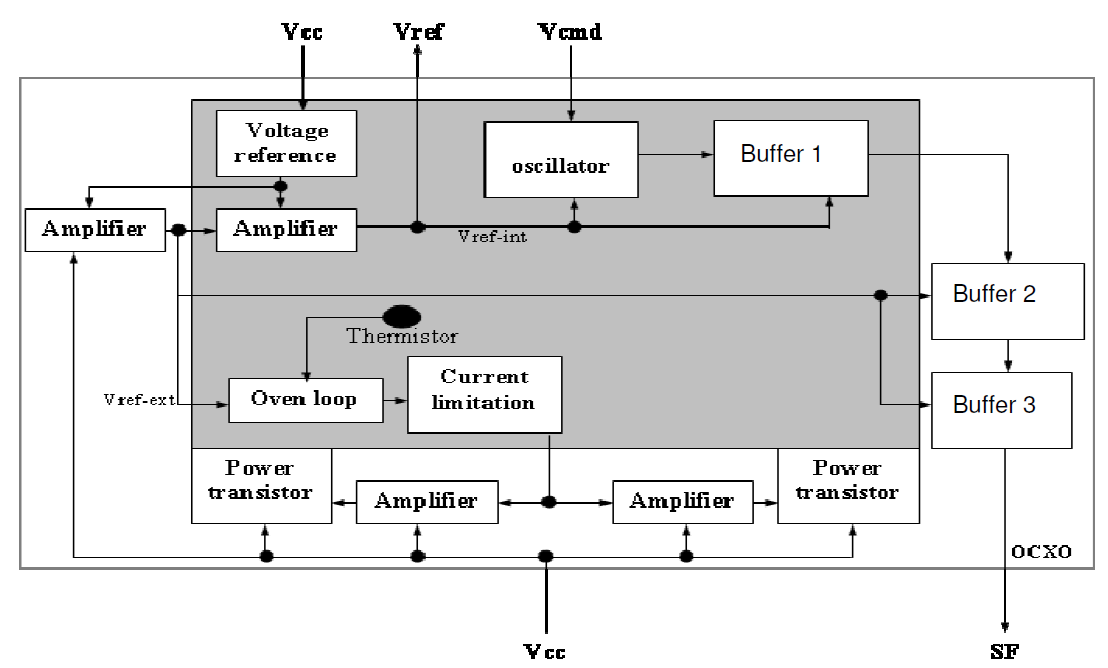

In the gray area of the block diagram are all the thermal sensitive functions which shall be implanted on the heated board.

Thermo-mechanical structure

The oven will be done by:

-

a small oven used to heat and fix the crystal resonator

-

a ground plane used to heat the PCB and the sensitive parts

-

machining a few slots on the PCB for thermal insulation

The plan is divided in two phases:

Phase 1: Requirements review and design

-

Task 1: Requirements, Technology and Design Modifications Review. Validation of LLI parts list.

PDR

-

Task 2: Detailed LNMO current design improvement:

-

5 MHz and 20MHz (SC overtone 3), 40MHz (SC overtone 5) crystals specifications in HC37 holder

-

Adding option of a second supply voltage.

-

Vs for signal generation supply

-

Vp for oven supply

-

-

-

Task 3: BBM manufacturing at 20MHz and 40MHz

-

Task 4: LLI purchasing and Crystals pre-irradiation

-

Task 5: Update MATV plan including crystal pre-irradiation process

-

Task 6: Establishment of the preliminary qualification test plan

CDR

Phase 2: Qualification

-

Phase 2 A: EQM Manufacture, Assembly, Tuning

-

Task 7: EQM manufacturing

-

Task 8: Finalization and validation of qualification test plan and test procedures

-

TRR

-

Phase 2 B: Qualification tests

-

Task 9: Environmental tests (vibration, thermal and mechanical shocks)

-

Task 10: Irradiation tests

-

Task 11: Thermal vacuum cycle

-

Task 12: EMC tests

-

Task 13: life test

-

Task 14: Overall Assessment and Recommendations

-

FR

Project completed.